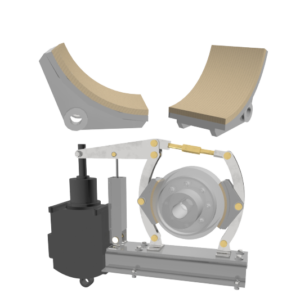

Brake shoes are widely used in machinery in general and especially for vehicles and railway brakes. In all cases, these brakes work by strongly pressing a shoe (made of either iron or steel covered with a special friction material) with a metal drum in motion (generally made of specially treated cast iron) with the intention of slowing it down or stopping it completely.

In some applications, such as trains, the shoe is in direct contact with the wheel.

Brake shoes are widely used in machinery in general and especially for vehicles and railway brakes. In all cases, these brakes work by strongly pressing a shoe (made of either iron or steel covered with a special friction material) with a metal drum in motion (generally made of specially treated cast iron) with the intention of slowing it down or stopping it completely.

In some applications, such as trains, the shoe is in direct contact with the wheel.

Remanufactured disks for oil immersed brakes are used in all types of heavy and agricultural machinery equipment. Its main benefit is represented by savings of up to 50% on the repair with the same performance as the original disk.

The SF friction plate is pre-molded, it has a groove that facilitates the flow of oil to cool down the brake system, thus allowing an optimal coefficient of friction, high performance, and low temperatures.

Brake shoes made from steel or cast iron have a woven friction material, which contains a high degree of flexibility, allowing them to adapt to different shoe diameters. Our sizing process guarantees an accurate compliance with the width, thickness, and length requirements made by our customers. It asbestos free.

MATERIAL DESCRIPTION

Woven friction lining for wet and dry applications.

Available in:

• Width: Up to 20 inches

• Thickness: From 3/16” to 1 1/2”

• Length: Up to 10 meters

Molded material with mineral fibers developed mainly for light/medium duty industrial applications.

• Its friction and mechanical properties make the SA92 a high-quality material exclusive to Motofrenos.

• It can operate with dry systems; it does not affect the metal parts in contact.

• Asbestos free.

Remanufactured disks for oil immersed brakes are used in all types of heavy and agricultural machinery equipment. Its main benefit is represented by savings of up to 50% on the repair with the same performance as the original disk.

The SF friction plate is pre-molded and it has a groove that facilitates oil flow to cool down the brake system, thus allowing an optimal friction coefficient, high performance, and low temperatures.

Remanufactured disks for oil immersed brakes are used in all types of heavy and agricultural machinery equipment. Its main benefit is represented by savings of up to 50% on the repair with the same performance as the original disk.

The SF friction plate is pre-molded and it has a groove that facilitates oil flow to cool down the brake system, thus allowing an optimal friction coefficient, high performance, and low temperatures.